1. Preparation

Remove old door (if applicable) using a pry bar and screwdriver.

Clean the rough opening of debris and old sealant.

Ensure the sill is level and opening is square.

2. Check Rough Opening Dimensions

Verify that the rough opening is approximately 1/2" to 3/4" wider and taller than the door frame to allow for proper shimming and insulation. Additionally, confirm the following:

The subfloor is level across the entire width of the opening, with a maximum allowable deviation of 1/4".

The side jambs are plumb (vertically straight).

The header is level, and the opening is square (diagonals should measure equally).

Accurate framing ensures smooth door operation, effective weather sealing, and long-term performance.

3. Assemble the Frame

If your door is shipped knocked-down (KD), assemble the frame per the manufacturer’s instructions.

Connect head, jambs, and sill with provided screws.

Ensure corners are square.

Use sealant between the jambs and sill connections for a watertight bond.

Add nailing flange if required:

Slide into the frame perimeter before assembling the frame.

4. Apply Waterproofing Caulking Beat

Apply a continuous bead of exterior-grade caulking along the floor line beneath the door and extend it at least 4 inches vertically up both jambs. This creates a watertight seal to help prevent moisture intrusion at the base of the opening.

If the door includes a nailfin flange, apply an additional bead of caulking behind the nail fin before setting the frame, ensuring a complete perimeter seal against water and air infiltration.

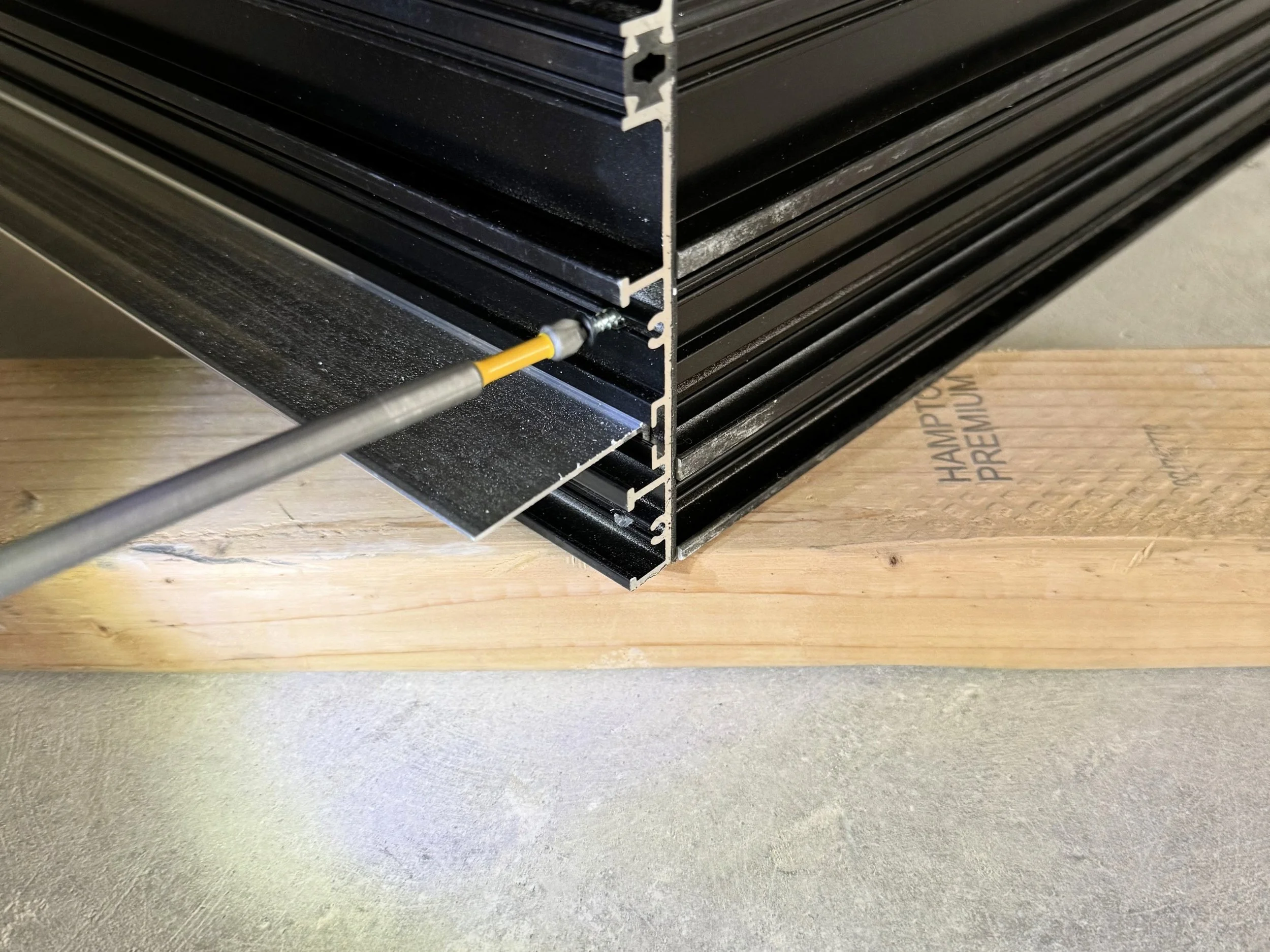

5. Set & Secure the Frame

Insert the frame into the prepared opening and press it firmly into place, verifying that it is square, level, and plumb. Use shims as needed to adjust and maintain proper alignment before fastening.

Fasten the frame through the nail flanges, typically every 16", using appropriate exterior-rated screws.

Additionally, install screws through the interior channels of the frame at the head and jambs to provide added structural support and prevent frame flexing or movement over time. (Add shims behind each screw on jambs)

Confirm the frame remains square during fastening to ensure proper panel operation.

6. Install Panels

Install the sliding panels into the track system by lifting each panel fully into the upper channel, then carefully lowering the bottom onto the track.

For best results, begin with the fixed panel, followed by the sliding panels in the correct sequence for your configuration.

Once in place, adjust the rollers as needed to ensure smooth operation and achieve consistent reveals along the head, jambs, and interlocks.

7. Seal, Flash and Insulate

Use exterior flashing tape around the top and sides of the frame.

Apply a continuous bead of exterior-grade sealant along the interior and exterior edges at the bottom of the frame (When possible). This enhances moisture resistance and ensures a more effective seal between the frame and the subfloor.

From the interior, apply low-expansion foam between frame and framing cavity.

Avoid overfilling to prevent frame distortion.

8. Final Checks

Ensure smooth operation, proper locking, and clean appearance.

Confirm weatherstripping makes good contact.

Clean off excess sealant and labels.